PHASE CHANGE HEAT TRANSFER

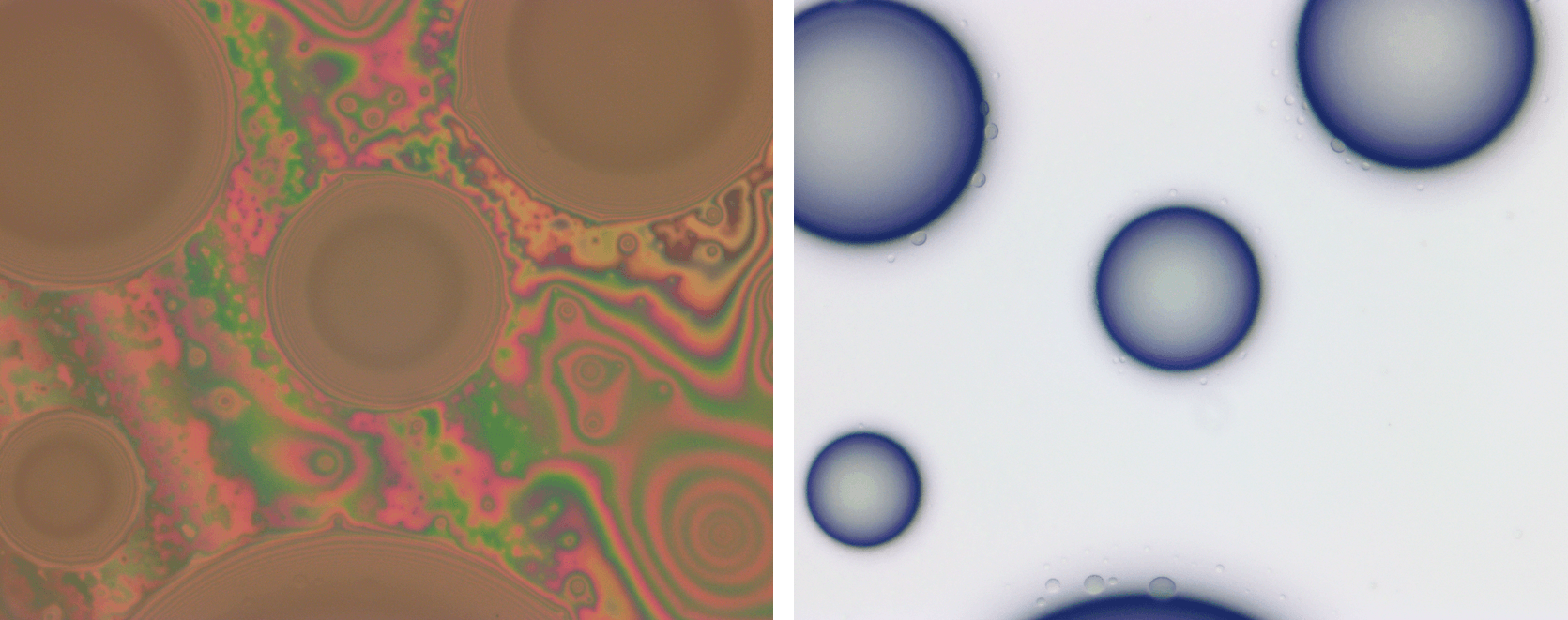

Heat transfer involving phase change (liquid -> vapor or vapor -> liquid) has among the highest heat transfer rates due to the latent heat of phase change. In this research group we focus on phase change phenomena on micro- and nanostructured surfaces, with an emphasis on (dropwise) condensation heat transfer. Recently, we also started exploring the influence of fluid mixtures on condensation heat transfer.

DROPLET (IMPACT) DYNAMICS

Droplet dynamics during impact on a solid surface are complex and very diverse. Using high speed optical and infrared (IR) imaging, we study the interplay of droplet dynamics, substrate dynamics, and heat transfer on various surfaces. We are furthermore interested in developing new techniques to manipulate droplet dynamics, either during and after impact, or of a droplet sitting on a surface.

Exemplary applications include thermal management, droplet based 3D printing, power generation, droplets as micro-reactors for bio-chemical assays, etc.

MELT POOL AND PARTICLE DYNAMICS DURING ADDITIVE MANUFACTURING

Additive manufacturing (“3D printing”) offers many advantages over traditional manufacturing technologies, such as versatility, complex structures, rapid prototyping, and in-situ alloying and compositional gradients. Together with Dr. Katharine Flores (WashU), we are investigating the thermal-fluidic interactions during metallic 3D printing, and their effect on workpiece quality.

We are also working on developing a manufacturing process that would allow to print multi-functional high-temperature polymer composites in collaboration with the Air Force.

FUNDING SOURCES